When a swimming pool or spa is to be constructed in a high-rise structure, the architect will design a rectangular recessed area in the floor where the pool or spa will be constructed. After the building is topped off, the pool contractor will then go in and do the final shaping for the finished pool. That was the case for the 229 foot tall apartment building constructed at 123 Linden Boulevard in Flatbush, Brooklyn, NY. The swimming pool and spa are located in an enclosed area on the top floor of the 20 story residential building.

The architect chose EPS15 Geofoam to shape the bottom of the pool. First the Geofoam was installed, then the woven wire was set in place, then the shotcrete was applied. If the taper at the bottom of the pool had been created with concrete, the additional weight would be 229,722 pounds. Crushed stone would have added 153,148 pounds, and sand would have been 148,554 pounds. The EPS15 Geofoam weighed just 1,379 pounds, less than one pound per cubic foot. With a compression strength of 520 pounds per square foot at 1% deformation, EPS15 Geofoam is used as lightweight void fill in dozens of applications from raised concrete floors to handicap ramps to the tiered seating in movie theaters.

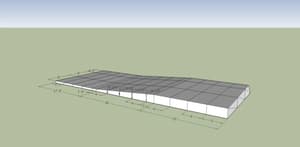

Anytime EPS can be used in place of heavier fill materials inside a structure, it is going to have a lower installed price than alternate fills. It does not require tamping. It can be placed with manual labor, not requiring any powered equipment to move it around. It is clean to work with, not creating any dust and it can be take up on a freight elevator as well as a crane. The shop drawing shows the configuration of the EPS geofoam as it was laid out by Universal Foam Products. Very little cutting was required to be done on site because the material was delivered precut, labeled and ready to install.