One of the increasingly popular uses for EPS Geofoam is the construction of stadium seating for commercial movie theaters and school and college lecture halls. EPS15 Geofoam is provided in precut blocks with each block labeled by tier and row. A drawing accompanies the blocks of foam showing the installation crew where each block is to be placed. Steel gripper plates are placed between layers locking them together. All of the pieces are precut requiring little if any modification on site. After the final tier is installed, the project is ready for concrete.

Stadium Seating Installation - Behind the Scenes

Leave-In-Place (LIP) Riser System Installation

The Leave– In-Place (LIP) riser form system simplifies and speeds up the construction process for new theaters, theater conversions, lecture halls, auditoriums and religious places of gathering.

The system, used in conjunction with EPS blocks to build the tiered seating, allows the contractor to form and pour a theater in a single day.

The Process

-

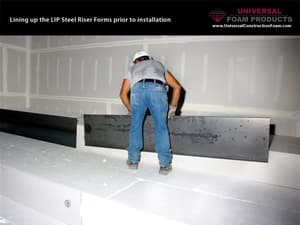

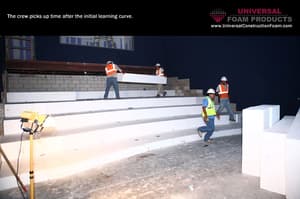

EPS blocks, most of which have been precut to size, are installed to create the desired tiered seating. The blocks, which are delivered to the site marked to coincide with construction drawings can be installed very quickly by stacking in place, using 4” x 4” steel gripper plates between layers to eliminate lateral movement.

-

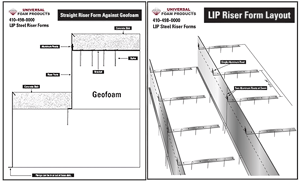

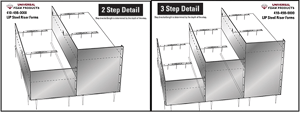

Next the prefabricated steel riser forms, which are 4” higher than the EPS blocks, are installed in front of the EPS tiers and secured in place using steel spikes and brackets which are pushed into the EPS blocks. The brackets are also riveted to the riser forms at approximately 24” on center. Step forms are prefabricated to the correct length and depth also.

-

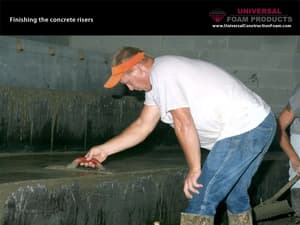

Once all the riser forms are secured, concrete installation can proceed. The thing that makes concrete installation unique with the LIP Riser System is that, using a pump truck, concrete is installed starting with the top tier and then moved down from there one tier at a time. **

Lip Riser System Installation

Benefits

-

Reduced construction time

-

Lower cost

-

Sound quality is approved due to sound dampening characteristics of expanded polystyrene

With conventional construction, steel framing and metal deck, the concrete installation starts at the top tier and is installed on every other tier moving down. This is because the space at alternate tiers is used to form the vertical face of the riser above. With this method, the concrete pump truck is needed two days to do a single theater or lecture hall.

Foam Installation for Stadium Seating

Theater Seating

EPS15 Geofoam was used to create the tiered seating of this major theater renovation. The historic Senator Theater in Baltimore Maryland was totally redone by AR Marani, a local Baltimore construction firm. Universal Foam Products also provided our proprietary Leave-In-Place Riser Form system which can be viewed in detail above. Universal provided the take-off and shop drawings for this part of the project. Most of the blocks were precut to size with very little fabrication required on site.

Senator Theater Renovation (Baltimore, Maryland)