Slurry walls are used in construction when a dry environment needs to be created in soil with a high water table. The new Parallel Thimble Shoal Tunnel Project in Virginia is such an environment where a second, parallel tunnel is being constructed to reduce traffic on the Chesapeake Bay Bridge Tunnel.

First the slurry wall forms, made of EPS15 geofoam, are set and anchored in place. The geofoam forms weigh less than 1 pound per cubic foot, making them easy to handle on site and are strong enough to withstand the lateral pressure of the concrete that is installed on both sides.

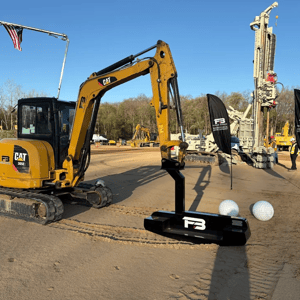

After the forms are set, reinforced concrete is installed on both sides of the EPS creating guide walls for the excavator that will dig the trench. The EPS forms are removed after the concrete guide walls are completed. Next an excavator is used to dig to a depth of 190’ using a slurry polymer to maintain stability of the deep excavation. After reinforcing cages are set in place in the excavation, concrete is pumped into the excavated area and the slurry mix is removed and either recycled or disposed of at a VDOE approved location. The area between the two 190’ deep reinforced concrete walls is now ready for the placement of the tunnel boring machine.