Due to its physical characteristics, expanded polystyrene (EPS) is an excellent source of floatation. It is used in conjunction with wood decking for floating docks and swim platforms. EPS may be encapsulated in concrete for much larger projects such as breakwaters.

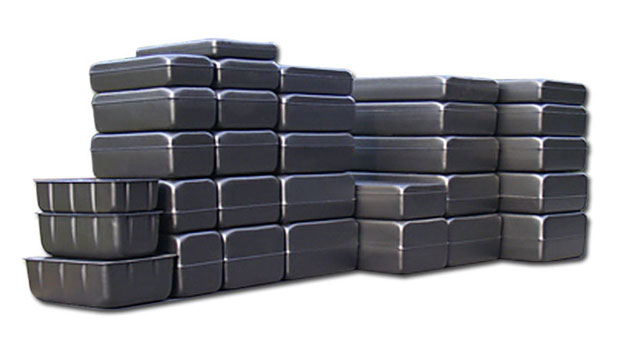

Formex® Encapsulated Floats

Since many public bodies of water now require floatation to be encapsulated, Universal Foam Products also offers a full line of encapsulated dock floats manufactured by Formex® that install quickly and are extremely durable.

32 Different Sizes In-Stock and Ready to Ship

You don’t have to limit yourself to a pre-built configuration. Your dock is as customizable as you want it to be. With 32 different HMWPE encapsulated float sizes in-stock and ready to ship, there�s no limit to building the ultimate floating dock.

Tough Outer Shells, Built to Last

Formex® dock floats are built using a rugged molded shell made from high density, high molecular weight polyethylene — a material which is also used for automotive gas tanks and canoes. The high tensile strength shell is resistant to impacts and is impermeable to water. The ultraviolet radiation resistant shell protects the foam core from wave action, animals, marine organisms, solvents and fuels.

Lightweight Expanded Polystyrene (EPS) Core

The inside of the Formex® floats are made from top grade expanded polystyrene (EPS) foam that conforms and thermally fuses to the shell. A pre-molded solid foam block means there is no loose fill and minimizes voids that can fill with water, reducing buoyancy. The foam is encapsulated using a patented process that allows the foam to be inspected before processing, insuring it is of the highest quality.

Installs Quickly and Easily

The floats mount directly to most any type of construction material using lag screws. Patented Quick Connect Strips (time tested feature that allows fast, secure, easy mounting) along the perimeter under the top surface allow attachment along their length or width. Quick Connect Strips (0.3" thick by 3.875" wide) are located horizontally along the perimeter under the top surface. Simplicity of design allows great flexibility while maintaining a positive strong attachment.

Reliable and Secure

Formex® dock floats have survived major hurricanes, remaining attached to docks that were decimated by the storms. Their reputation for quality and integrity has brought customers from every state. Formex® dock floats have a 12-Year Limited Warranty and meets U.S. Army Corps of Engineers Regulations. You won’t find a more solid and reliable dock flotation system anywhere!

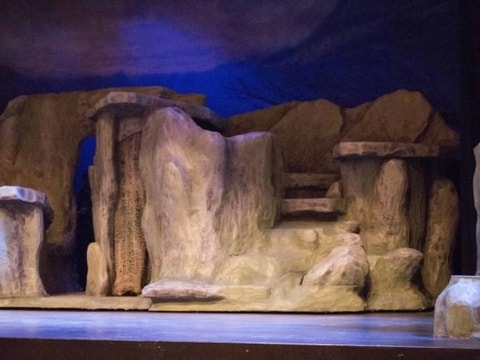

Unencapsulated EPS Flotation

Custom Flotation Solutions

When Walsh Construction needed to float a 31,000 lb Coffer Dam Cell out into the Susquehanna River they contacted Universal Foam Products for the best floatation material for the project. Universal recommended 4 large blocks of 1 lb EPS for the job. The structure was lowered onto the EPS blocks with a crane and was towed to the required location without incident.