For this renovation project in Northeast Washington, DC, the contractor needed to raise the floor elevation by 16”. The architect specified EPS19 geofoam which was provided by Universal Foam Products. The EPS19 geofoam has a compression strength of 840 pounds per square foot at 1% deformation. The material was delivered in 12” x 48” x 96” panels, each weighing just 37 lbs (1.6 pounds per square foot). The geofoam panels were laid on the existing slab, then woven wire was installed, then the concrete was installed using a pump truck. The 12” geofoam and 4” slab added 51.6 pounds per square foot to the underlying slab. Had sand or gravel fill been used, the additional load would have been 190 pounds to 200 pounds per square foot. For this particular project all 8 of the unique characteristics of EPS geofoam made it the logical decision.

Geofoam vs Organic Fill Material – Comparison

When examining the various fill materials available for a project there are a number of factors to consider. Compression strength is probably the most significant. Material cost is an important factor. Labor to install can be a significant cost. Weight of the material. The most often used fill materials are EPS geofoam, sand, aggregate, gravel and stone. Each material will best fit the requirements of a particular scenario. Often a combination of fill materials required to provide best solution.

One material is unique among all fill materials – EPS geofoam. What makes it unique?

EPS geofoam comes in block and sheet form. It can also be provided in

shapes (tapers and curves)

EPS geofoam is extremely lightweight, weighing between .7 lb and 2.8 lbs

per cubic foot

EPS geofoam has compression strengths up to 18.6 psi (2,680 psf, 128

kPa) at 1% deformation

EPS geofoam requires no tamping and will not settle over time. It

installs fast – reducing both construction time and labor cost

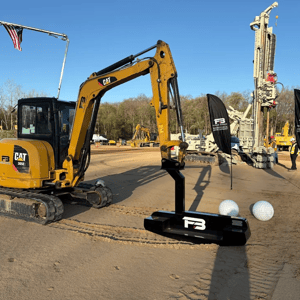

EPS geofoam requires no heavy equipment to install. It can be installed

using manual labor.

EPS geofoam is a clean fill material, ideal for interior renovation

projects

EPS geofoam ships from locations throughout the United States making it

LEED friendly

EPS geofoam is quiet to work with making it ideal for tenant fit-out and

remodeling applications.