A slurry wall is a reinforced concrete wall, particularly used in top-down construction for deep permanent structures.

Slurry – a polymer and water mixture – fills an excavated trench to prevent soil excursions. Reinforcement structures are then added, followed by concrete inserted with tremie tubes which displaces the slurry.

The slurry wall process causes no vibration and minimal noise; ideal for unstable soil conditions. It is a time-saving, top-down construction method where walls are needed at great depth such as basements. Thick walls can be produced that stand high load strength. Excellent for seepage and water control, slurry walls are used extensively for dams, sewage and for holding tanks. Slurry walls are also known as known as continuous diaphragm walls or seepage cut-off walls.

Popular Applications for slurry walls

-

Earth retention walls for deep excavations

-

Basements walls – faster construction time than other methods

-

Top-down construction method for unstable soil conditions.

-

Deep shafts and tunnels

-

Retaining wall-foundations

-

Top-down construction method for permanent basement walls

-

Bridge foundations and cut-and-cover tunnels

-

Vibration control and underpinning

-

Sewage projects

-

Groundwater, dams and seepage control

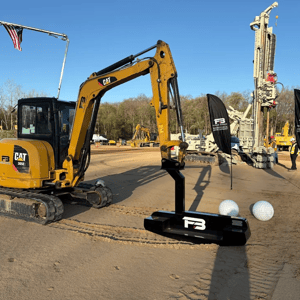

Construction of the guide wall

Trench Excavation

The trench is started – cutting in alternate panel sections – using a mechanical or hydraulic clamshell. Usually two temporary stop end tubes are inserted at the end of each section.

Addition of slurry

The liquid slurry fills the trench, acting as back pressure to stop soil incursion. It is a mix of water and a polymer powder – usually bentonite. This bentonite slurry is mixed on site. The clamshell continues to work through the slurry.

Reinforcement insertion

Reinforcement is added into the trench; often a large metal cage or rebar depending on the nature of the wall.

Concreting using tremie pipes

Finally the permanent concrete is poured into the trench using tremie pipes. The concrete displaces the slurry upwards which can be retained and sometimes reused. Stop pipes are removed and the next alternate panel section is started.

Choosing slurry walls using EPS forms

Initial excavation and preparation includes accurate placement of a concrete guide wall, produced with precisely shaped forms. For a curved or circular top-down construction in particular, EPS forms make this vital first step much easier and quicker. Made to precise dimensions from clients’ specifications and much lighter and easier to move around site.

-

EPS forms are produced to tight tolerances to contain the slurry

-

EPS secant forms are created offsite then shipped ready to use. Less space and time required onsite.

-

EPS forms are lightweight to move and set in place; less disruptive in difficult soil or site conditions that traditional steel or timber forms.