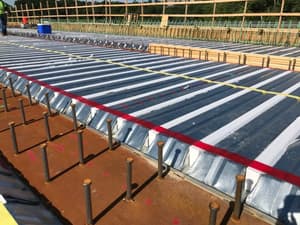

EPS flute fillers were used to lighten the weight of this bridge being constructed over the Merrimack River in Haverhill Massachusetts.

Bridge deck flute fillers made of lightweight expanded polystyrene are required to be used in bridge construction in many states. The light weight flute fillers, which are pre-cut to the shape of the flutes in the steel bridge decking, keep concrete from entering the flutes when it is being installed. In those states requiring the flute fillers, it has been determined that concrete going into the flutes adds to the weight of the bridge without adding to the structural integrity of the project. Filling the steel deck flutes with EPS weighing less than 1 lb per cubic foot, instead of concrete, weighing 150 lbs per cubic foot, can reduce the weight of a bridge by hundreds of thousands of pounds. The reduction in weight often means a reduced cost of structural components, lowering the cost of the bridge to tax payers.

The flute fillers on this particular project weighed just over 2,000 pounds and took the place of 343,000 pounds of concrete. The cost of the flute fillers is also substantially lower than the installed cost of the concrete they replace.

As our highways and bridges age and deteriorate, it is necessary to innovate and reduce the cost of replacing them. In 2017 the Washington Post ran an article stating that over 55,000 bridges in the United States needed to be replaced or repaired. The Federal Highway Administration estimates an annual investment of $20.5 billion is needed over the next 16 years to repair and replace bridges. Moving forward, smart engineers need to look at ways to reduce the cost and increase the functional life of new bridges. Using EPS flute filler to lighten the load is one step in that direction.