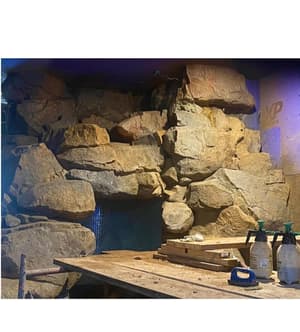

Universal Foam Product’s customer, Spencer Dean Creations, is an expert when it comes to creating Faux Rock scenery. Spencer Dean Creations used Expanded Polystyrene Foam Blocks on this project to give them the ability to mock things up quickly, as well as, eliminate and keep weight to a minimal. This was especially true for the ceiling, with the Expanded Polystyrene Foam being a very lightweight material. The customer carved the shapes of the Foam Blocks using various knives, rasps, and sanders. They then used 1/4” rebar and chicken wire over the foam and sprayed a proprietary fiber reinforced concrete for the structure coat. A specialty cement plaster coat was used on top of that to finish with the detailed sculpting.