TerraFlex™ Elasticized Geofoam is beneficial when rehabilitating or retrofitting existing structures by adding an increased safety factor against one or more geotechnical and/or structural failure mechanisms such as seismic forces and expansive soils and rock.

Other materials such as bales of hay or straw, wood chips, and cardboard have been used in compressible inclusion applications worldwide since the early 20th Century. However, these materials are unpredictable in their mechanical and physical behavior.

Using TerraFlex™ Elasticized Geofoam will provide predictable and consistent mechanical (stress-strain-time) behavior that is totally under the control of the design engineer.

TerraFlex™ is a revolutionary geosynthetic product with the following attributes:

-

Increased compressibility compared to normal EPS (TerraLite™ Geofoam)

-

Predictable mechanical behavior

-

Provides thermal insulation

-

Provides noise and vibration damping

-

Will not decompose

-

Will not contaminate the environment

-

Recyclable

-

Resistant to insect infestation

Composition and Materials: TerraFlex™ Elasticized Geofoam is a cellular plastic material that is strong, but has very low density (1% of traditional earth materials). The parent material, TerraLite™ Geofoam, is a manufactured block material meeting the engineered product specification standards of ASTM C 578 and CGSB 51.20. The nominal (average) density of the parent material is 12 kg/m3 (.75 lb/ft3).

TerraFlex™ Elasticized Geofoam contains Perform Guard®.* Perform Guard is made under a patented process** which uses a natural mineral that is formulated to resist insects and builds it right into the product.

TerraFlex™ is unaffected by normally occurring weather at time of installation and will retain its physical properties under pre-engineered conditions of use. TerraFlex™ is made under a Quality Assured manufacturing process monitored by a third party laboratory.

Size and Shape: TerraFlex™ is produced in block form and is easily fabricated to required dimensions for individual projects. The molded blocks have dimensions of 901.7 mm (35.5") x 1257.3 mm (49.5") x 4927.6 mm (194.0"). The blocks are then subjected to an additional manufacturing process of elasticization that increases the flexibility characteristics of the material.

Environmentally Safe: TerraFlex™ contains no CFC’s, HCFC’s, HFC’s, or formaldehyde. It is inert, non-nutritive and highly stable. It will not decompose, decay, or produce undesirable gases or leachates. TerraFlex™ is recyclable and safe for WTE Systems and landfills.

Limitations and Cautions: TerraFlex™ stands up well to normal weather conditions encountered during installation. Long-term (6 months or greater) exposure to UV radiation will cause discoloration. Material should be covered as soon as practical.

TerraFlex™ is unaffected by freeze thaw cycling, moisture, or road salts. Protect TerraFlex™ from exposure to hydrocarbons, highly solvent extended mastics and coal tar pitch.

TerraFlex™ contains a flame retardant additive; however, it should be considered combustible and should not be exposed to open flame or any source of ignition.

Applicable Standards: TerraFlex™ is a proprietary product with physical properties that have been altered during the manufacturing process of elasticization. The parent material, TerraLite™, is manufactured with third-party (UL) certification to be in compliance with ASTM C 578 Type XI specifications. The block molding process of the parent material also includes additional voluntary, proprietary quality control standards and additives of GeoTech Systems Corporation.

*Tested against termites and carpenter ants. Manufacturer has specific

species on file. Perform Guard is a registered trademark of the AFM

Corporation.

**Protected under U.S. Patents No. 5,194,323 and No. 5,720,108. Other

U.S. and Foreign Patents Pending. 1997 AFM Corporation.

Technical Data: To select the required thickness of TerraFlex, the design professional should develop project-specific design curves relating deformation of the ground surface and stress at the ground surface from the expanding ground. In general, the largest stress occurs under confined (zero deformation) conditions and the largest deformation occurs under free-swell (zero stress) conditions. The designer must select a magnitude of surface stress and corresponding deformation that is intermediate to these limiting conditions and for which the structure will be designed.

Note: In the absence of data relating surface stress and deformation, the designer can use deformations estimated using free-swell tests and arbitrarily select a stress level for which the structure will be designed.

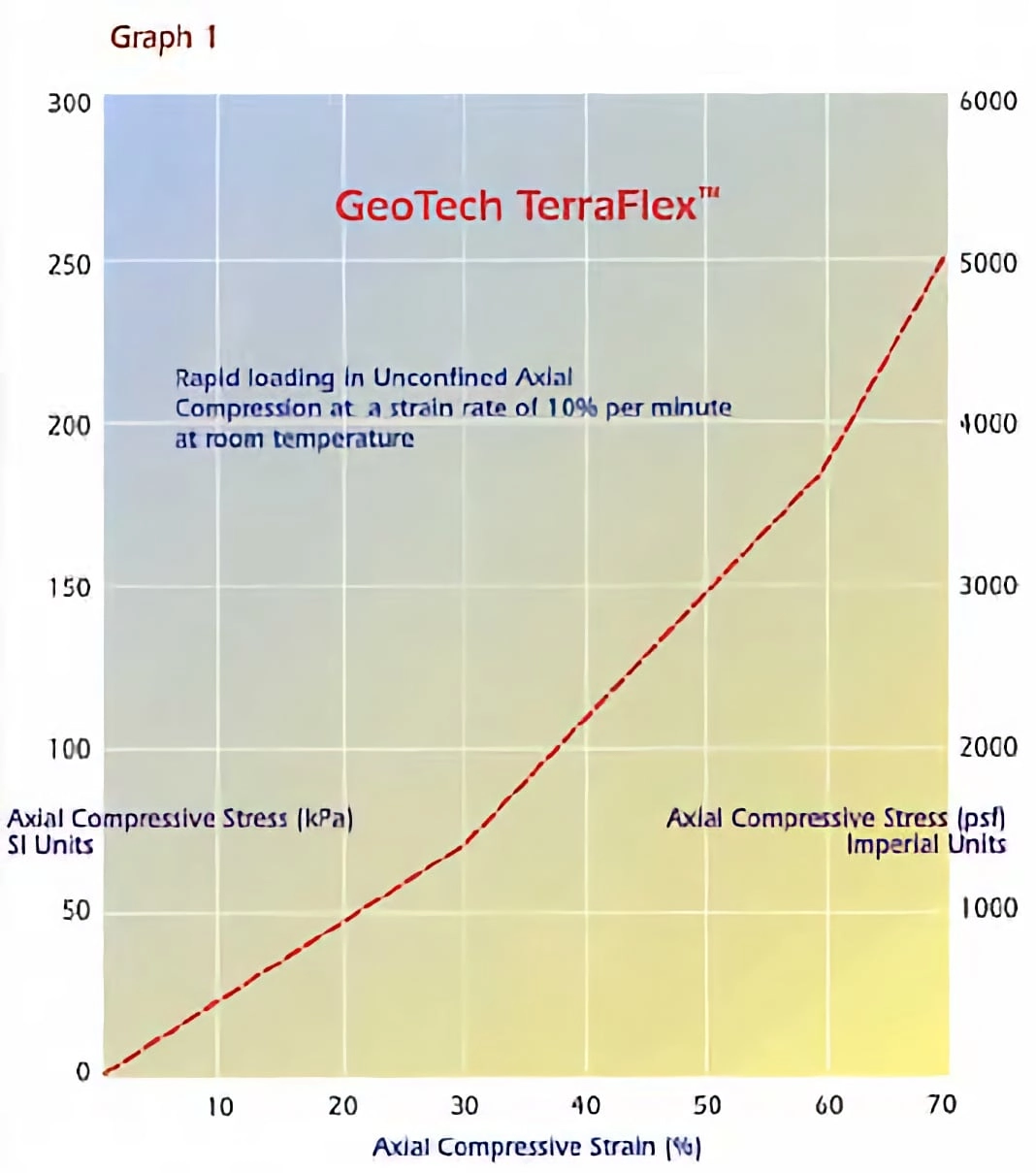

Graph 1 shows the stress-strain relationship of TerraFlex™ Elasticized Geofoam in rapid loading, unconfined axial compression at a strain rate of 10% per minute at room temperature. To determine the thickness of TerraFlex™ required for project specific conditions Graph 1 is used to estimate the strain level in the Geofoam.

-

Find the stress magnitude for which the structure will be designed on the vertical axis.

-

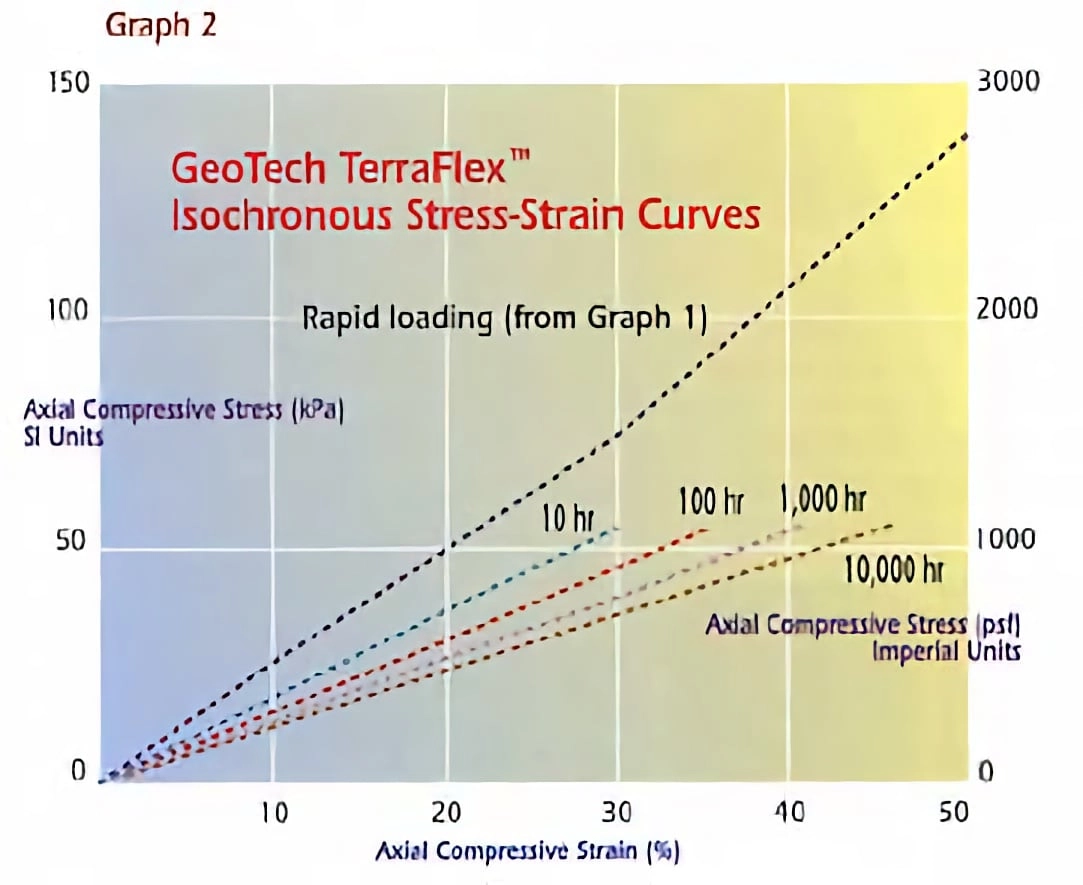

Move horizontally to the appropriate stress-strain curve. For the most conservative design, the rapid loading curve should be used. For greater economy under conditions when the ground expansion is expected to develop over an extended period of time, one of the extended time curves in Graph 2 can be used. For geofoam strains greater than approximately 40%, only the rapid loading curve should be used.

-

Move vertically downward and scale off the corresponding Geofoam strain level.

The required thickness of Geofoam is the calculated using the following equation:

\[Geofoam\ Thickness = { {Design\ magnitude\ of\ surface\ deformation * 100} \over { TerraFlex™\ strain \% } } \]

Using this simple approach, different combinations of stress transmitted to the structure and Geofoam thickness can be evaluated to find the most cost effective design.

Graph 2 shows isochronous stress - strain curves for different

durations of loading for TerraFlex™ Elasticized Geofoam.

The stress-strain curves were developed using the results of unconfined

axial compression creep tests.

Installation: TerraFlex™ Elasticized Geofoam can be used in the following applications. Other engineered applications may also be appropriate.

-

Earth retaining structures.

-

Culverts

-

Buried Pipes

-

Bridge abutments,

-

Bermed structures, and

-

Slabs on grade.

For most applications the following guidelines apply. Additional guidelines for specific applications should be developed by the design engineer.

-

At time of material delivery, verify Quality Assurance and identification marks on face of the product.

-

Surfaces should be clean, dry and sound; free of excessive dust, dirt, loose paint, oil, grease or any foreign matter that would interfere with a good bond.

-

Apply OSI QB-300 (or equal) adhesive to TerraFlex. Place walnut sized daubs of adhesive alternately spaced every 8" - 12" apart across the surface of the TerraFlex™ board, beginning 3" from the edges.

-

Set TerraFlex™ board in place immediately. Press firmly over the entire surface to level board and establish good adhesive contact. Butt all board joints tightly.

NOTICE: The information contained herein is, to the best of GeoTech’s knowledge, accurate and reliable as of August 1998. Freedom from patents of GeoTech or others is not to be inferred. For any information that may have been developed subsequent to August 1998, consult the nearest GeoTech sales office.